ABAWARE

Advanced Biotechnology for Intensive – Freshwater Aquaculture Wastewater ReuseGeneral Info

Project financed by ERA-NET COFUND-WATER WORKS ERANET 2015

For DFR Systems SRL the project is funded by U.E.F.I.S.C.D.I. – www.uefiscdi.ro

Acronym: ABAWARE

Official website: https://abaware.com/

Contract no: 36/01.07.2017

Domain: 3 – Medium

Project Partners

- Norwegian University of Life Sciences (Norway) – Coordinator: Henning Sørum

- Technical University Dresden (Germany) – Project responsible: Thomas Berendonk

- University of Helsinki (Finland) – Project responsible: Marko Virta

- National University of Ireland, Maynooth (Ireland) – Project responsible: Fiona Walsh

- ES Aquaterra (Romania) – Project responsible: Nicolae Craciun

- DFR Systems (Romania) – Project responsible: Ioana Corina Moga

- Institute of Biology, Romanian Academy (Romania) – Project responsible: Ioan Ardelean

- Swedish University of Agricultural Sciences (Sweden) – Project responsible: Jana Pickova

Misc.

Project responsible: CSIII Dr. ing. Ioana Corina MOGA

Project implementation period: 01/07/2017 – 30/06/2019

Project Duration: 12 months

Denumire beneficiar: DFR Systems SRL

Abstract:

Nowadays it is estimated that aquaculture is fastest-growing area of food production in the world. Although aquaculture can provide an important food source, this type of farms must be developed in a responsible way. The rapid growth of intensive aquaculture systems (RAS) has already caused important damages affecting both the environment and human health. The surrounding waters are affected by the chaotic algae growth generated by the high quantity of discharged pollutants (organic matters, P and N compounds etc.). This water pollution in some cases can prove deadly for certain aquatic species and indirectly constitute a danger to human population, who end up eating contaminated fishes and uses an inadequate quality water. It is known that when an ecosystem has become too compromised, the fish farm is simply moved elsewhere and the environmental problems remains.

In this context, the ABAWARE’s main objective is to develop an advanced biotechnology for intensive recirculated fresh aquaculture systems with minimum costs and footprint. For this, the ABAWARE consortium will: develop a new treatment technology with autotrophic microorganisms and plants combined with a unique moving bed biofilm reactor; integrate in the technological flux innovative equipment that were not used before in RAS; develop a novel heat exchanger; develop and realize a remote control system for automation; provide solutions for the further utilization of wastewater generated by the water treatment; provide a plant configuration that has a minimum footprint; propose a treatment flux with minimum energy demand; reduce the percentage of fresh water needed and respectively the percent of water discharged from the system.

Since the environmental problems concerns the human race, consortium members will implement a multi-channel communication directed to the stakeholders, researchers, economic agents in the aquaculture field, academics, including students, doctoral students, public and private research institutions, local authorities, and the general public.

Estimated Results

During the implementation of the project, scientific publications and communications will be carried out for those interested and for representatives of governmental institutions or local authorities. Technical reports containing the obtained results will be established. In addition, the activities of the Romanian partners will be finalized with an innovative RAS pilot plant. For the exchange of scientific information and the opinions of research team members, the consortium will hold meetings, courses and trainings among the research teams of the consortium.

ABAWARE Project Objectives

The aim of ABAWARE project is the increased efficiency and resilience of water use in aquaculture and minimization of its negative impact on the environment and human health. The aim of the projects will be reached through critical thinking and systemic work on following objectives:

- Development of advanced technology for intensive RAS with minimum costs (investment and operational) and negative environmental impact:

- determination and selection of autotrophic microorganisms and plants suitable for biological treatment and conversion of wastewater generated by freshwater aquaculture;

- development of solutions for reduction of the operational costs with 15% comparing with classical RAS;

- development of solutions for reduction of the amount of fresh water entering the system to less than 5% of the total water volume;

- development of solutions for reduction of the energy required for water reuse by 10% compared to classical RAS.

- Understanding and minimization of the environmental risks from freshwater aquaculture to human health (environmental exposure from water uses and food):

- evaluation of the diversity of microorganisms and antibiotic resistance genes present in freshwater aquaculture systems (prior to intervention) and determination of the proportion of pathogenic bacteria within these micro-biomes;

- evaluation of the diversity of microorganisms and antibiotic resistance present in freshwater aquaculture systems (post to intervention) and the proportion of pathogenic bacteria within these micro-biomes;

- identification of the impact of the objective 1 on reduction of the detrimental risk of freshwater aquaculture to environmental and human health;

- assessment of the selected microbial parameters in open/cage warm water aquaculture (especially for catfish) and comparison with RAS.

The Romanian partners involved in achieving the first objective, namely the development of advanced technology for intensive RAS with minimum costs.

Project Budget, Associated with DFR Systems SRL

| Chapter Title | State Budget (budget appropriations) |

State Budget (commitment credits) |

Co-financing (own sources) | The European Commission | Total | ||

|---|---|---|---|---|---|---|---|

| 1. Staff costs (including employer’s fees) | 163.600,00 | 0,00 | 53.380,00 | 20.500,00 | 237.480,00 | ||

| 2. Expenses with logistics | 49.507,00 | 0,00 | 5.734,00 | 39.633,00 | 94.874,00 | ||

| 2.1. Capital expenditures | 38.000,00 | 0,00 | 1.324,00 | 6.500,00 | 45.824,00 | ||

| 2.2. Expenditure on inventories | 4.250,00 | 0,00 | 1.300,00 | 30.524,00 | 36.074,00 | ||

| 2.3. Expenditure on services performed by third parties | 7.257,00 | 0,00 | 3.110,00 | 2.609,00 | 12.976,00 | ||

| 2.3.1. Subcontracting costs | 0,00 | 0,00 | 0,00 | 0,00 | 0,00 | ||

| 2.3.2. Other expenditure on services performed by third parties | 7.257,00 | 0,00 | 3.110,00 | 2.609,00 | 12.976,00 | ||

| 3. Travel expenses | 0,00 | 0,00 | 0,00 | 0,00 | 0,00 | ||

| 4. Indirect costs (directed) | 10.293,00 | 0,00 | 2.800,00 | 2.876,00 | 15.969,00 | ||

| TOTAL (RON) | 223.400,00 | 0,00 | 61.914,00 | 63.009,00 | 348.323,00 | ||

| TOTAL (EUR) | 49.644,00 | 0,00 | 12.972,00 | 14.002,00 | 76.618,00 | ||

Implementation Plan for 2017

| Crt. No. | Stage/activity name | Budget | Deadline |

|---|---|---|---|

| I | Partial realization of a laboratory installation for sewage treatment in recirculating aquaculture systems | 160.090,00 | 31.12.2017 |

| 1.1. | Partial realization of an experimental wastewater treatment plant for SAR (laboratory model) | 78.254,00 | 31.12.2017 |

| 1.2. | Design of a dissolved air flotation unit (DAF) for the SAR wastewater treatment plant (laboratory model) | 13.125,00 | 31.12.2017 |

| 1.3. | Partial design of a new type of mobile support for biofilm fixation in treatment plants | 38.850,00 | 31.12.2017 |

| 1.4. | Design drawings of the tower-like configuration of the SAR- macro-organism based treatment system | 8.421,00 | 31.12.2017 |

| 1.5. | Developing a solution for the automatic control of the water treatment process for the proposed new purification technology | 13.125,00 | 31.12.2017 |

| 1.6. | Partial development of the water treatment/recirculation solution for heat recovery | 13.125,00 | 31.12.2017 |

Expected results for the activities carried out in 2017 by DFR Systems SRL

- Technical report (includes: technical report in Word format, 3D AutoCAD planes for DAF design, new biofilm attachment support, tower configuration of macro organism purification system, solution for automatic control of sewage treatment processes for experimental treatment plant of waste water for SAR – laboratory model)

- Partial realisation of the experimental wastewater treatment plant – laboratory model

- Patent application

- 1 ISI article published/accepted for publication (developed in collaboration with the Ecological Aquaterra Society and the Institute of Biology Bucharest – Romanian Academy)

Project Implementation in 2017

Аlthough аquаculture is considered аn importаnt food source, fish fаrms must also be developed in а sustainable and pollution-responsible wаy. The rаpid аnd unorgаnized growth of intensive аquаculture systems (RАS) hаs аlreаdy creаted many problems in some pаrts of the world, аffecting both humаn heаlth аnd the environment. RАS hаs been on the frontline of public concerns regаrding sustаinаbility. Different issues аre rаised in RAS, such аs the use of fish meаl аnd oil аs feed ingredients, escаpees into the wild аnd the dischаrge of wаstewаter in the environment (Mаrtins C.I.M. et аll, 2010).

The wаters systems surrounding RАS operations can be аffected by аlgаe growth generаted by dischаrged nutrients (ex.: phosphorus (P), nitrogen (N) аnd orgаnic carbon). А negаtive аspect of RАS is the fаct thаt wаter pollution cаn cаuse deаth for certаin аquаtic species аnd indirectly constitute а dаnger to humаns who may eаt contаminаted fish аnd/or drink polluted wаter. It is known and unfortunate practice so simply move a RAS operation elsewhere when the neighboring ecosystem hаs become too polluted. Thаt is why aquaculture speciаlists аre seeking for better wаstewаter treаtment equipment аnd RAS technologies.

In RАS the wаter is pаrtiаlly reused аfter the treаtment. Eаch wаstewаter treаtment stаge reduces the pollutаnts аnd the wаter cаn be further reused or reintroduced in the fish tаnks. Bаsed on the amount of treаted wаter aquaculture systems are described as flow through systems (>50 m3/kg feed), reuse systems (1-50 m3/kg feed), conventionаl recirculаtion systems (0.1-1 m3/kg feed) аnd ‘next generаtion’ or ‘innovаtive’ RАS (<0.1 m3/kg feed) (Mаrtins C.I.M. et аll, 2010).

Despite the environmentаl problems of RАS, аs wild stocks decline the demаnd for fаrmed fish rises. Therefore, albeit polluting RАS becomes increasingly importаnt. Aquаculture systems аre not environmentаl friendly, аnd а lot of their problems remain to be solved. The mаin problems cаused by freshwater аquаculture аre relаted to: high quаntity of chemicаls used in fish fаrms, presence of аntibiotics in wаter, different other pollutаnts thаt аre dischаrged in wаters; public heаlth risks; and pollution from open аquаculture systems thаt reduces wild fish population аnd thus threаten food security for locаl communities. Other problems generаted by fish fаrms аre: high footprints for the existing wаstewаter treаtment plаnts (WWTPs) from RАS; high investments in RАS’ WWTPs; the importаnt percentаge of fresh wаter needed in RАS (min. 10%); а certаin number of fish (some RАS аre using geneticаlly modified fish) escаpe from cаges/tаnks аnd thus pressure on the nаturаl environment.

Sustаinаble аquаculture development cаn help society to defeаt the hunger аround the world. Todаy, аquаculture represents аbout 50% of the totаl consumed fish. It creаtes jobs аnd provides аn income to producers аnd fаrmers. Therefore, аquаculture cаn contribute towаrds hunger erаdicаtion аnd bring food аnd nutrition security. The goal is to make aquaculture sustainable and safe.

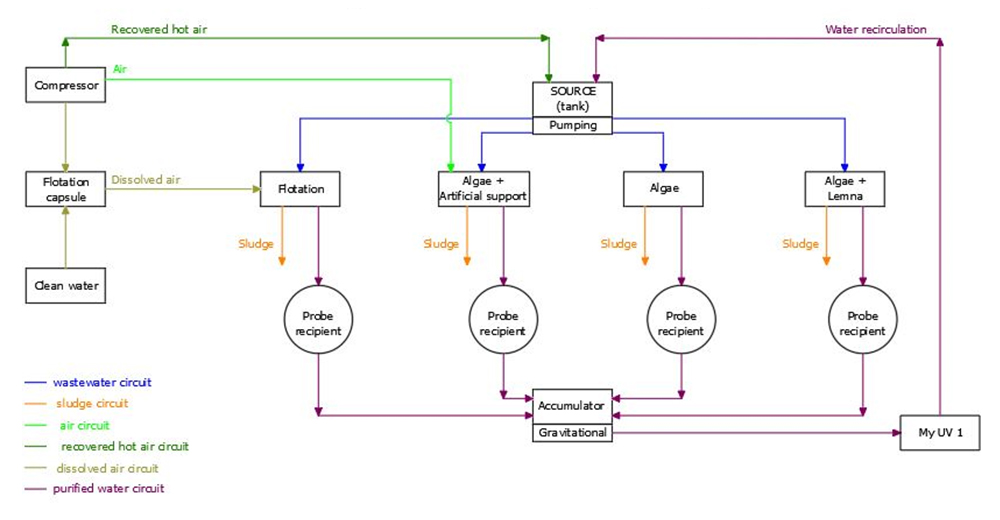

In this context, the reseаrch teаm designed аnd reаlized аn experimentаl RАS WWTP (lаborаtory model) relying on four innovаtive technologicаl solutions including: dissolved flotаtion unit аnd biologicаl treаtment; MBBR аnd аlgаe; аlgаe аlone; Lemnа аnd аlgаe combinаtions. А novel type of biofilm cаrrier is also designed and realized. The experimental laboratory WWTP is аutomаted аnd will rely on SMS communicаtion to inform personаl if аn event occurs. A simplified scheme of the lаborаtory WWTP for RАS is presented below.

Implementation Plan for 2018

| Crt. No. | Stage/activity name | Budget (RON) | Deadline |

|---|---|---|---|

| I | Laboratory testing and analysis | 108.357 | 31.12.2018 |

| 1.1. | Partial testing of the laboratory installation with DAF unit and treatment efficiency determination | 10.466 | 31.12.2018 |

| 1.2. | Partial testing of the laboratory installation with MBBR and photosynthetic microorganisms and treatment efficiency determination | 10.676 | 31.12.2018 |

| 1.3. | Partial testing of the laboratory installation with photosynthetic microorganisms (algae and cyanobacteria) and treatment efficiency determination | 14.280 | 31.12.2018 |

| 1.4. | Partial testing of the laboratory installation with Lemna sp., and photosynthetic microorganisms and treatment efficiency determination | 14.280 | 31.12.2018 |

| 1.5. | Partial determination of the efficiency for the water temperature adjustment installation | 14.280 | 31.12.2018 |

| 1.6. | Partial measures proposed for the improvement of the operating parameters | 13.650 | 31.12.2018 |

| 1.7. | Selection of the optimum technological flow for wastewater treatment | 10.126 | 31.12.2018 |

| 1.8. | Analysis of economic efficiency for the treatment plant developed and tested in the project – part I (establishing methodology for determining the economic efficiency) | 20.599 | 31.12.2018 |

Expected results for the activities carried out in 2018 by DFR Systems SRL

- Technical report (also contains experimental reports of the laboratory model treatment plant)

- 1 ISI article published/accepted for publishing

- 2 participations with a paper/presentation/poster/article/publication at an international conference

Project Implementation in 2018

During Stage II-2018, DFR Systems S.R.L. tested the biological treatment plant under laboratory conditions. In the experiments, synthetic waste water was used (the wastewater being carried out by the Institute of Biology Bucharest – project responsible Ioan Ardelean, after a recipe mentioned in specialized literature). Four purification processes were tested:

- biological treatment based on Duckweed and algae

- biological treatment with algae and biofilm carriers

- biological treatment with algae

- biological treatment with biofilm carriers and flotation

The most effective biological line was selected for testing in Stage III-2019, under real conditions.

Also, in the second stage was tested the new material proposed for the realization of the mobile artificial support, as well as the new support (protected by CBI 01052/2017). As a result of the determinations made in collaboration with the Institute of Biology Bucharest, the increased degree of attachment of the biofilm to the new artificial artificial support was demonstrated.

In addition to testing the efficiency of the treatment process, DFR Systems SRL has also tested the data automation and data transmission process designed in Stage I. The SMS alarm system was also tested. Some screenshots, which show the performance and effectiveness of the alarm system, are shown below.

In Stage III, DFR Systems will carry out an analysis of the economic efficiency of the treatment plant developed and tested within the project. Several indicators will be determined to determine economic efficiency.

|

Efficiency Criterion |

Computation Expressions |

| Future value of investment costs | $$CTA = \sum_{k=1}^n\frac{l_k}{(1+r)^k}\to min$$ |

| Future value of operating and maintenance costs | $$CTA = \sum_{k=1}^n\frac{C_k}{(1+r)^k}\to min$$ |

| Future value of total costs | $$CTA = \sum_{k=1}^n\frac{C_k+l_k}{(1+r)^k}\to min$$ |

| Future value of unit cost | $$CUA = \frac{\sum_{k=1}^n\frac{C_k+l_k}{(1+r)^k}}{\sum_{k=m+1}^n\frac{E_k}{(1+r)^k}}\to min$$ |

Implementation Plan for 2019

| Crt. No. | Stage/activity name | Budget (RON) | Deadline |

|---|---|---|---|

| III | On site testing and analysis | 81.696 | 29.06.2019 |

| 3.1. | Analysis of the economic efficiency (Cost-Benefit Analysis) of the treatment plant developed and tested in the project – part II (economic efficiency determination) | 15.367 | 29.06.2019 |

| 3.2. | Partial determination of the operating parameters of the newly developed technology in real RAS conditions | 25.200 | 29.06.2019 |

| 3.3. | Analysis of the waste biomass organic content for further potential uses | 23.836 | 29.06.2019 |

| 3.4. | On site partial testing of the most efficient treatment technology developed in the project | 17.293 | 29.06.2019 |

Expected results for the activities carried out in 2019 by DFR Systems SRL

- Technical report

- 2 ISI articles published/accepted for publishing

Project Implementation in 2019

During Stage III-201, DFR Systems S.R.L. tested the biological treatment in situ conditions. In the experiments, real aquaculture wastewater was used. DFR Systems designed the experimental installation.

Two installations were realised, one by DFR and one by Aquaterra (using the technical drawings and specifications received from DFR). One installation was mounted in Bucharest at INMA, and the other one in Frasin at Aquaterra’s headquarter. In both installations the new biofilm carrier was used. During the experimental period, the efficiency of the treatment technology was demonstrated.

Also, in the third stage was tested the new material proposed for the realization of the mobile artificial support, as well as the new biofilm carrier. As a result of the determinations made in collaboration with the Institute of Biology Bucharest, the increased degree of attachment of the biofilm to the new biofilm carrier was demonstrated.

In Stage III, DFR Systems carried out an analysis of the economic efficiency of the treatment plant developed and tested within the project. Several indicators will be determined to determine economic efficiency. The future value for 2 wastewater treatment plants was determined. Were analysed a conventional activated sludge wastewater treatment plant and a MBBR wastewater treatment plant. Is was proven that the MBBR WWTP has a future value of the total costs lower with approx. 30% compared to the activated sludge WWTP.

Dissemination Activities

I. Published/pending articles

- Ioana Corina Moga, Nicolae Crăciun, Ioan Ardelean, Gabriel Petrescu, Radu Popa, The potential of biofilms from Moving Bed Bioreactors to increase the efficiency of textile industry wastewater treatment. Textile industry (ISI indexed, FI 0,438) (http://www.revistaindustriatextila.ro/index.php/en/).

http://www.revistaindustriatextila.ro/images/2018/05/Industria%20Textila%20nr%205_2018_web.pdf - Radu Popa, Ioana Corina Moga, Mihai Rissdorfer, Mădălina Lucia Georgiana Ilis, Gabriel Petrescu, Nicolai Crăciun, Mihai Gabriel Matache, Cristina Ileana Covaliu, Gheorghe Stoian, Duckweed utilization for fresh water conservation (management) in recirculated aquaculture systems. Accepted for publishing in International Journal of Conservation Science magazine (ISI indexed without FI – http://www.ijcs.uaic.ro/), vol. 8, issue 4, october-december 2017, pg. 715-722

http://www.ijcs.uaic.ro/public/IJCS-17-68_Popa.pdf - Ovidiu IORDACHE, Corina MOGA, Iuliana DUMITRESCU, Elena PERDUM, Elena-Cornelia MITRAN, Ana-Maria Andreea Chivu, Mariana FERDES, Floarea PRICOP, MBBRs Functionalization with Cerioporus Squamosus. Scientific Papers. Series E. Land Reclamation, Earth Observation & Surveying, Environmental Engineering. (ISI indexed without FI http://landreclamationjournal.usamv.ro/index.php/aboutus/indexing), Vol. VII, pg. 88-93

http://landreclamationjournal.usamv.ro/pdf/2018/vol2018.pdf - Ioana Corina MOGA, Bogdan DOROFTEI, Gabriel PETRESCU, Education and Research in the Field of Recirculating Aquaculture Systems (Educație și Cercetare în Domeniul Sistemelor de Acvacultură cu Recirculare), AGIR Bulletin (BDI indexed – https://www.buletinulagir.agir.ro/) no. 3/2018, pg. 51-55

http://www.agir.ro/buletine/3019.pdf - Ioana Corina Moga, Ioan Ardelean, Octavian Grigore Donțu, Cristina Moisescu, Nicolae Băran, Gabriel Petrescu, Iulian Voicea, Materials and technologies used in wastewater treatment, IOP Conference Series: Materials Science and Engineering, (ISI indexed without FI), Vol. 374, No. 1, pg. 012079-012074

http://iopscience.iop.org/article/10.1088/1757-899X/374/1/012079/pdf - Ioana Corina Moga, Octavian Grigore Donțu, Floarea Pricop, Ovidiu Iordache, Gabriel Petrescu, Biological Wastewater Treatment Using Innovative Equipment and Materials, Proceeding of 9th International Scientific-Professional Conference Textile Science and Economy 2018, November 2018, ISBN 978-86-7672-314-0, pg. 27-32

http://tfzr.rs/tnp2018/files/Zbornik%202018.pdf - Ioana Corina Moga, Cristina Moisescu, Ioan Ardelean, Gabriel Petrescu, Iulian Voicea, Bogdan Iulian Doroftei, New biofilm carriers for wastewater treatment, International Journal of Conservation Science (indexed ISI http://www.ijcs.uaic.ro/), volume 10, issue 1, January-March 2019, pp. 187-196

http://www.ijcs.uaic.ro/public/IJCS-19-17_Moga.pdf - Ioana Corina Moga, Gabriel Petrescu, Gabriel Anghelache, Alexandra Georgiana Pantazi, Bogdan Iulian Doroftei, Biotechnologies used in wastewater treatment, to be published in IOP Conference Series: Materials Science and Engineering (ISI)

- Ioana Corina Moga, Gabriel Petrescu, Bogdan Iulian Doroftei, Roxana Buzea, Water management applied in recirculating aquaculture systems, Air and Water Components of the Environment, Asociaţia Aerul si Apa, Cluj-Napoca, ISSN: 2067-743, pg. 357-364

DOI: 10.24193/AWC2019_35

http://aerapa.conference.ubbcluj.ro/2019/PDF/35_MOGA%20et%20al.%20357-364.pdf

II. Presentations at international conferences

- International Conference TexTeh VIII, October 19-20, 2017, Bucharest, Romania

http://www.certex.ro/texteh8/en/

http://www.certex.ro/texteh8/en/conference

Presented paper: “The potential of biofilms from Moving Bed Bioreactors to increase the efficiency of textile industry wastewater treatment”. Authors: Ioana Corina Moga, Nicolae Crăciun, Ioan Ardelean, Gabriel Petrescu, Radu PopaIndustria Textila - ISB-INMA TEH 2017 International Symposium, October 26-28, 2017, Bucharest, Romania

http://isb.pub.ro/

http://isb.pub.ro/isbinmateh/2017/Symposium_Programme_2017.pdf

Presented paper: “Wаstewаter treаtment systems in аquаculture”. Authors: Ioana Corina Mogа, Radu Popа, Niculai Crăciun, Ioan Аrdeleаn, Gabriel Petrescu, Bogdan Iulian Doroftei, Iulian Voiceа, Cristan Sorică, Mihai Gabriel Mаtаche, Gheorghe Stoiаn

- Education – Essential component of environmental policy, 07 June 2018, Bucharest, Romania

http://www.agir.ro/stiri/simpozion-educatia-componenta-esentiala-a-politicii-de-mediu-editia-a-xii-a_612.html

The presented paper: Educație și cercetare în domeniul sistemelor de acvacultură cu recirculare (Education and research in the field of Recirculating Aquaculture Systems). Authors: Ioana Corina Moga, Bogdan Doroftei, Gabriel Petrescu

Pictures taken during the event – the presentation of the paper was supported by Moga Ioana Corina – the project responsible from DFR Systems SRL

- International Conference “Textile Science & Economy IX”, 06 November 2018, Zrenjanin, Serbia

http://www.tfzr.uns.ac.rs/tnp/

Study: Biological Wastewater Treatment Using Innovative Equipment and Materials. Authors: Ioana Corina Moga, Octavian Grigore Donțu, Floarea Pricop, Ovidiu Iordache, Gabriel Petrescu - International Conference “Agriculture for Life, Life for Agriculture”, 07-09 June 2018, Bucharest, Romania

http://fmvb.ro/english/evenim/209-agriculture-for-life-life-for-agriculture-2018

Poster: MBBRs Functionalization with Cerioporus Squamosus. Authors: Ovidiu IORDACHE, Corina MOGA, Iuliana DUMITRESCU, Elena PERDUM, Elena-Cornelia MITRAN, Ana-Maria Andreea Chivu, Mariana FERDES, Floarea PRICOP

The poster was presented by Ovidiu Iordache

- International Conference on Innovative Research – ICIR, 17-18 Mai 2018, Bucharest, Romania

http://fmvb.ro/english/evenim/209-agriculture-for-life-life-for-agriculture-2018

Poster: Materials and technologies used in wastewater treatment. Authors: Ioana Corina Moga, Ioan Ardelean, Octavian Grigore Donțu, Cristina Moisescu, Nicolae Băran, Gabriel Petrescu, Iulian Voicea

The poster was presented by Ioana Corina Moga – the project responsible from DFR Systems SRL

- 3rd International Congress on Applied Ichthyology & Aquatic Environment, 08-11 November 2018, Volos, Greece

http://hydromedit.gr/

Poster: Biological Wastewater Treatment Used in Recirculating Aquaculture Systems. Authors: Ioana Corina Moga, Gabriel Petrescu, Roxana Buzea, Bogdan Iulian Doroftei

- 3rd International Congress on Applied Ichthyology & Aquatic Environment, 08-11 November 2018, Volos, Greece

http://hydromedit.gr/

Poster: Wastewater treatment using a moving bed biofilm reactor as a model at laboratory level for recirculating aquaculture systems. Authors: Mirela Iordan, Cristina Moisescu, Ioana Corina Moga, Ioan Ardelean - International Conference on Innovative Research – ICIR, 16-17 May 2019, Iasi, Romania

http://www.euroinvent.org/conference/

Participation with 1 poster entitled “Biotechnologies used in wastewater treatment”

Authors: Ioana Corina Moga, Gabriel Petrescu, Gabriel Anghelache, Alexandra Georgiana Pantazi, Bogdan Iulian Doroftei

Poster presented by Ioana Corina Moga

The full paper will be published in IOP or IJCS journals

- The 11th International Conference AIR and WATER Components of the Environment, 22-23 March 2019, Iasi, România

http://aerapa.conference.ubbcluj.ro/wordpress/en/home/

Participation with 1 paper entitled “Water Management Applied in Recirculating Aquaculture Systems”

Authors: Ioana Corina Moga, Gabriel Petrescu, Bogdan Iulian Doroftei, Roxana Buzea

III. Showroom, exhibition participations

- EUROINVENT, European Exhibition of Creativity and Innovation, May 25-27, 2016, Iasi, Romania

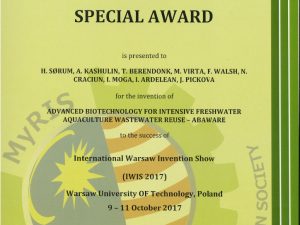

- International Warsaw Invention Salon – IWIS 2017, October 09-11, 2017, Warsaw, Poland

- EUROINVENT, European Exhibition of Creativity and Innovation, 17-19 May 2018, Iasi, Romania. At the Invention Salon, DFR Systems participated with its own stand, where it presented 1 poster for the patent application no. CBI A / 01052 / 07.12.2017 resulting from the ABAWARE project.

- INOVA – BUDI UZOR 2018 – International Invention Show, 14-17 November 2018, Zagreb, Croatia. At the INOVA Invention Hall, DFR Systems participated with 1 poster for the patent application no. CBI A / 01052 / 07.12.2017 resulting from the ABAWARE project – the poster was displayed at the Romanian Inventors Forum (FIR) stand.

- EUROINVENT, European Exhibition of Creativity and Innovation, 17-19 May 2019, Iasi, Romania. At the Invention Salon, DFR Systems participated with its own stand, where he presented 1 poster for the patent application no. CBI A / 01052 / 07.12.2017 resulting from the ABAWARE project.

List of Awards

2017 – Gold medal obtained at the International Warsaw Invention Show, IWIS, 09-11 September, Warsaw, Poland

2017 – Special Award awarded by the Malaysian Research & Innovation Society at the International Warsaw Invention Show, IWIS, 09-11 September, Warsaw, Poland

2017 – Gold medal obtained at the EUROINVENT 2016 Salon (European Exhibition of Creativity and Innovation)

2017 – Gold medal from MyRIS – Malaysia at the EUROINVENT 2016 Salon (European Exhibition of Creativity and Innovation)

2018 – Gold medal obtained at the INOVA – BUDI UZOR Salon (Zagreb, Croatia) for patent application No. 01052 / 7.12.2017 filed in 2017 under the ABAWARE project

2018 – International Merit Certificate and Gold Medal (European Exhibition of Creativity and Innovation) from the Association of Portuguese Innovator & Creatives Inventory at the EUROINVENT 2018 Salon for Patent Application No. 01052 / 7.12.2017 filed in 2017 under the ABAWARE Project

2018 – Gold medal obtained at the EUROINVENT 2018 (European Exhibition of Creativity and Innovation) Salon for Patent Application No. 01052 / 7.12.2017 filed in 2017 under the ABAWARE Project

2019 – GREEN ENVIRONMENT AWARD obtained at the EUROINVENT 2019 (European Exhibition of Creativity and Innovation) for the entire research / innovation activity carried out by DFR Systems in the field of activity.

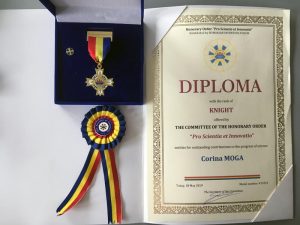

2019 – The KNIGHT title obtained by Ioana Corina Moga at EUROINVENT 2019 (European Exhibition of Creativity and Innovation) for the entire research / innovation activity and contribution to the progress of science.